Welcome to Vortex

Depollution & Recycling Equipment

Our equipment is

robust, easy to use and reliable

Our designs make the tools operator friendly and reduce maintenance, thereby increasing productivity, as we make the products ourselves we can very easily change things to suit the customers circumstances.

Designed & manufactured

In the USA

Welcome to

Vortex Vehicle Depollution & Recycling Equipment

Vortex is a market leader in the design and manufacture of vehicle drain equipment for end of life vehicles as well as top equipment distributors for the metal recycling industry.

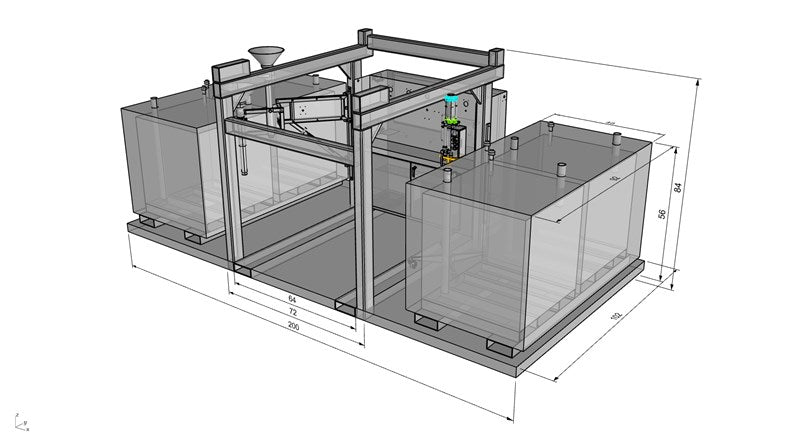

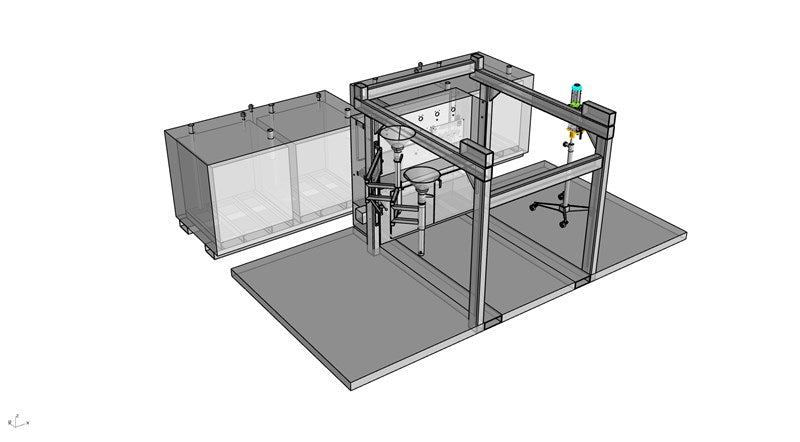

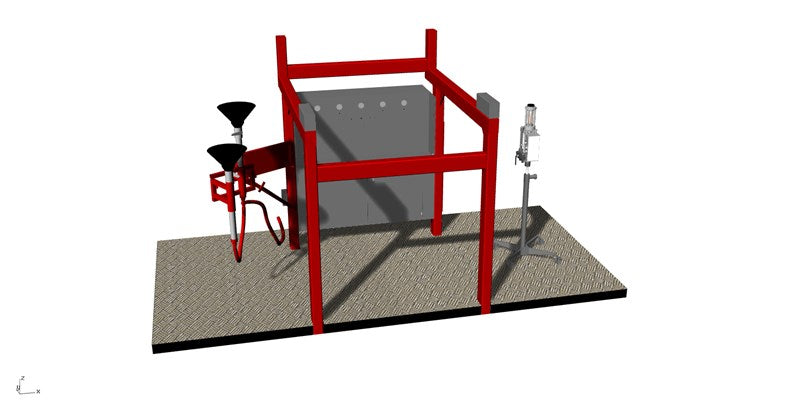

Vortex Depollution designs and manufactures vehicle drain equipment that will make your yard compliant with environmental or state requirements as well as getting the job done in a cleaner, safer and more efficient way. With more than 20 years’ experience within the industry, every one of our vehicle depollution and recycling tools has been engineered with the operator in mind. From efficient tool placement, with ergonomic design and space to work, through to the use of ATEX/UL explosive zone rated equipment in all our designs, we have systems to suit your needs. Ranging from equipment that work seamlessly with your lift or rack to stand alone tools, fully customized systems and turnkey installations with compressors, storage tanks and full plumbing.

Here at Vortex we understand the vehicle recycling industry and are therefore committed to maximizing your profits by processing as much of the vehicle as possible. We make and supply equipment to crush the engines in order to maximize aluminum recovery, process wire harnesses to increase copper recovery, and process catalytic converters to fully recover the platinum group metals contained within. When all this is done, we also supply Roter car balers to maximize your load capacity going to the shredder.

For the scrap metal recycling industry, we supply a range of nonferrous processing equipment, such as McIntyre Alligator shears, nonferrous balers, cable strippers, shredders, car and metal balers, shear balers, container tilters, and loaders. We also supply casting and pelletizing machinery for the aluminum smelting industry.

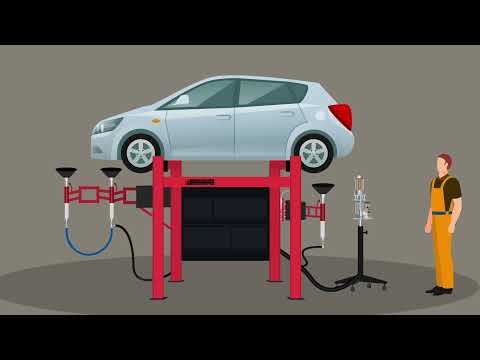

Vehicle Drainage

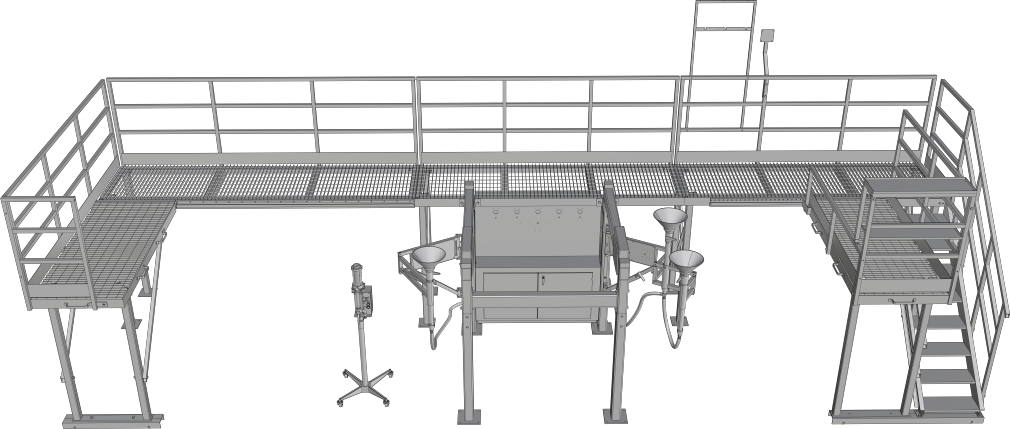

Catwalk Systems

All of our systems have been developed as a way of lifting the vehicle on to a rack where it has every process done to the vehicle, touching the vehicle only once with the loader or fork lift.

Once in place the full vehicle can be processed at the same time, the fluids recovered from under the vehicle at the same time as the fluids from under the hood, the cat can be cut off and the trash taken out of the vehicle. With the full catwalk systems the wheels can be removed on the rack as well.

Full Service

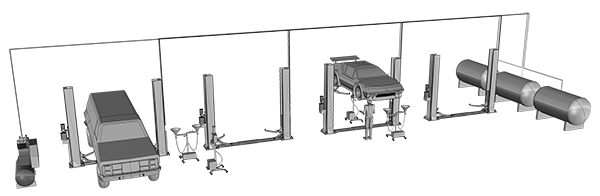

Auto Parts Systems

Designed for the full service auto parts industry, the are designed to be moved between vehicle lifts to drain all the fluids from under the vehicle and the engine bay before the vehicle is dismantled.

With the correct plumbing system, which we can install, the tools simply plug in to the outlet ports on each leg of the pipework and the onboard pumps move the recovered fluids out of your building to outside storage tanks. One set of tools is normally enough to cover 4 vehicle lifts.

Testimonials

“I can process over 40 cars a day with Vortex and it has revolutionised the way I do business”

D. Williams

"The new rig makes the job of de-polluting ELV's much safer, cleaner and more efficient"

Lee Sands - Site Manager, Sims Metal Management - Wimborne

“Cars can be de-polluted a lot faster with the new Vortex system which allows me more time for removing parts.”

John Leach - ELV Operator, Sims Wimborne

“The new combi system has improved operator productivity by optimising the de-pollution process. One of the ways this has been achieved is by Vortex including all of the tooling on the rig where the operator needs them so minimal time is wasted in tool set up. Having had a combi system in a production environment for the last four months it is noticeable how much more reliable it is compared with other equipment and how it has improved over previous systems, but what is most impressive is how much our operators like using it.”

Rob Taylor - Group ELV Business Manager, Sims Metal Managment

“The Vortex equipment has made it a lot easier for the operators to use and they take pride in looking after it which has helped with reducing maintenance costs.”

Chris Lock - Regional Manager, Sims Metal Management - Avonmouth

“We chose Vortex because of the build quality and because Vortex were willing to work around our previous set up and enhance it tremendously. Mike, Pete and Gordon were very helpful. If we need more de-pollution kit in the future I am sure we will buy Vortex.”

Jim Maguire - Abbey Metal Recycling, Cinderford